"Same as VH but with additional EasyClean feature which will help remove all dirt online at mere turn of a knob without having to open the valve / filter mesh. Or needing a plumber to clean the filter"

The VH is to be used when higher o/p pressures (above 5 bar) are needed which the standard W3 cannot support (though the range of VH is 1.5 to 10 bar). This need arises mostly in hydropneumatic type systems and where PRVs have to be installed in basement only ( and not in ducts outside apartments) for reasons like ease of access; limited space in duct; or inaccessible ducts .

Pressure Reducing Valves protect household water installations for industrial or commercial applications within the range of their specification. By installing a pressure reducing valve, pressurisation damage is avoided and water consumption is reduced. The set pressure is also maintained constant even when there is wide inlet pressure fluctuation. Reduction of the operating pressure and maintaining it at a constant level minimizes flow noise in the installation. The VL is specialy designed for lower outlet pressure without compromising on the flow rate. These are especially used when more then 4 branches are drawn from one downtake line and the last branch tends to get very high pressure in spite of using a PRV.

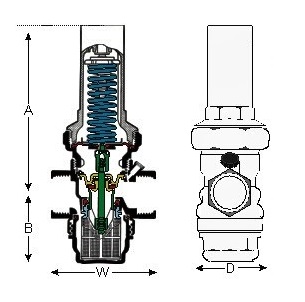

| SIZE (MM) | W | A | B | D |

|---|---|---|---|---|

| 25 | 104 | 119 | 73 | 76 |

| 32 | 107 | 119 | 73 | 76 |

| 40 | 120 | 153 | 125 | 85 |

| 50 | 120 | 153 | 125 | 85 |

*OPTIONAL Easy Clean feature in VH-SC variant.

Has built in filter of SS304 with Standard 200 micron filter and with easy cleaning attachment.

General Specifications of VH

| Medium : | Water, compressed Air, Nitrogen |

| Max Inlet Pressure : | 16 bar # |

| Outlet Pressure Range : | 1.5 to 10 bar * |

| Max Temperature: | 45 deg Celcius.70 deg Celcius (for hot water applications) |

| Sizes | 25 to 50 mm |

| End connections | BSP female threaded |

| Body | Gun Metal/ Bronze |

| Spring | Spring Steel |

| Built in Filter | SS316 mesh 400microns |

| Easy cleaning feature | only in VH-SC variants |

| Warranty | 10 years |

# higher temperatures and pressures available on request

* See W3 & VH for higher outlet pressure ranges

"Same as VH but with additional EasyClean feature which will help remove all dirt online at mere turn of a knob without having to open the valve / filter mesh. Or needing a plumber to clean the filter"